Conquering the Wire Harness Connector: A Comprehensive Guide

Ever stared at a tangled mess of wires, feeling a creeping sense of dread? We've all been there. Whether it's a flickering car headlight, a malfunctioning appliance, or a temperamental piece of electronics, the culprit often lies within that mysterious network: the wire harness. And at the heart of that harness? The connector. This seemingly small component plays a crucial role, acting as the bridge between different parts of an electrical system. But what happens when that bridge collapses? This is where understanding how to replace a wire harness connector becomes essential.

Imagine the electrical system in your car as a complex highway system, with currents flowing like vehicles. The wire harness is the network of roads, and the connectors are the crucial interchanges, allowing the electrical flow to reach its destination. A faulty connector is like a blocked intersection, causing traffic jams and system failures. Knowing how to navigate this repair is like having a roadmap to clear the blockage and restore smooth flow.

Replacing a wire harness connector might sound daunting, but it's often a more manageable task than completely rewiring a system. It’s a skill that can empower you to tackle common electrical issues, saving you time and money. This guide breaks down the process, offering a comprehensive overview of wire harness connector replacement, from understanding the basics to troubleshooting common challenges.

The history of wire harness connectors is intertwined with the development of electrical systems themselves. As technology advanced, so did the need for more sophisticated and reliable connection methods. Early connectors were often simple, soldered joints, prone to failure and difficult to repair. Over time, more robust and modular connectors emerged, allowing for easier replacement and maintenance. This evolution continues today, with ongoing innovations in connector design and materials.

The importance of proper wire harness connector replacement cannot be overstated. A poorly executed replacement can lead to a range of issues, from intermittent connections and system malfunctions to more serious problems like short circuits and even fires. Understanding the correct techniques and procedures is crucial for ensuring a safe and reliable repair.

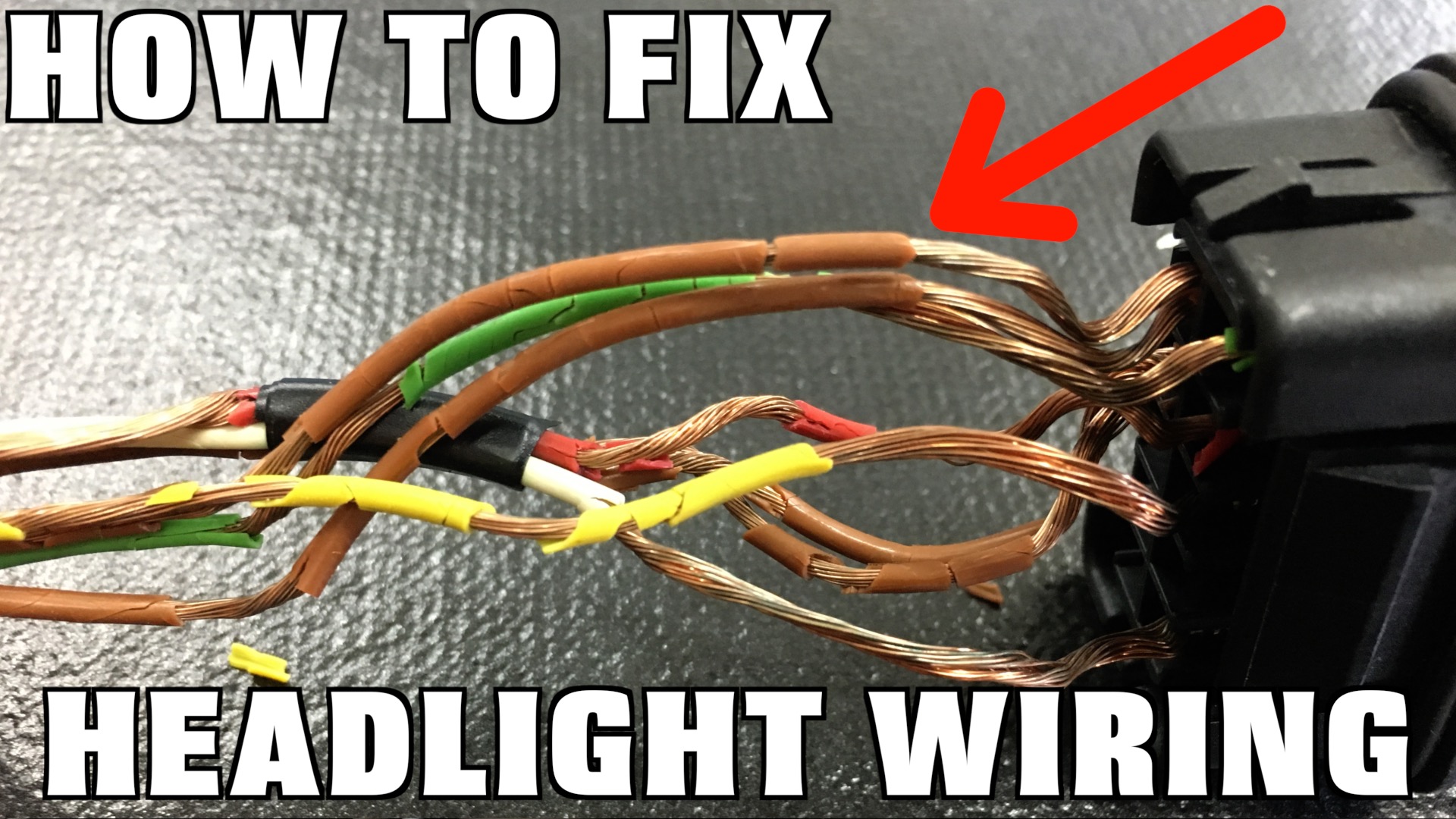

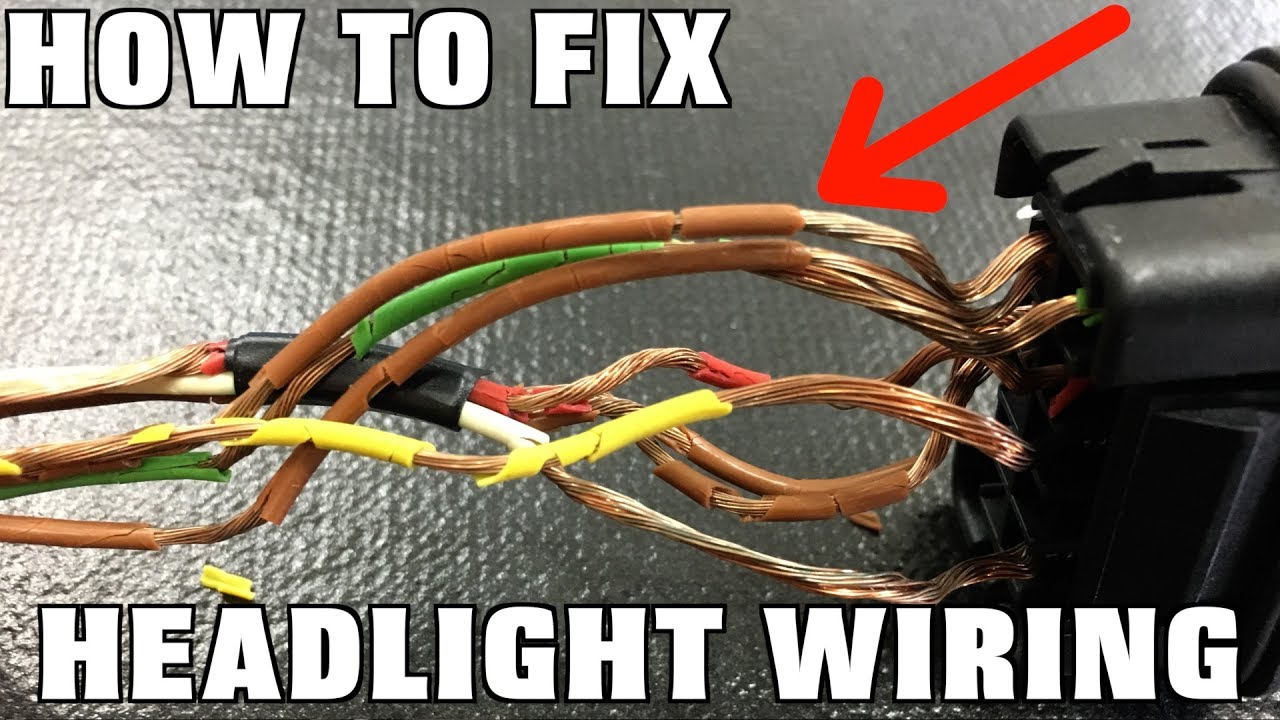

A wire harness connector is essentially a housing that contains multiple terminals, each corresponding to a specific wire in the harness. These terminals are designed to mate with corresponding terminals on another connector, creating a secure electrical pathway. For example, the connector for your car's headlight allows power to flow from the battery, through the harness, and to the bulb. Replacing this connector involves disconnecting the old one, identifying the correct replacement, and properly attaching it to the harness.

Benefits of Replacing a Wire Harness Connector:

1. Cost-effective: Replacing a connector is often significantly cheaper than replacing the entire wire harness.

2. Time-saving: Connector replacement is usually a quicker fix than more extensive wiring repairs.

3. Improved reliability: A new connector can restore the integrity of the electrical system, preventing future problems.

Steps to Replace a Wire Harness Connector:

1. Disconnect the battery or power source.

2. Identify the faulty connector and disconnect it from the harness.

3. Obtain the correct replacement connector.

4. Carefully connect the new connector to the harness, ensuring proper alignment and secure connection.

5. Reconnect the battery or power source and test the system.

Advantages and Disadvantages of Replacing a Wire Harness Connector

| Advantages | Disadvantages |

|---|---|

| Cost-effective repair | Requires some technical skill |

| Time-saving solution | Potential for incorrect installation |

| Improved system reliability | May require specialized tools |

Frequently Asked Questions:

1. How do I identify the correct replacement connector? Consult your vehicle or appliance's service manual or contact a parts supplier.

2. What tools do I need? Basic hand tools like screwdrivers and pliers are usually sufficient.

3. Can I replace a connector myself? Yes, with proper research and caution.

4. Where can I purchase replacement connectors? Auto parts stores, electronics suppliers, and online retailers.

5. What if the new connector doesn't fit? Double-check the part number and compatibility.

6. How do I prevent future connector problems? Regular inspection and maintenance can help.

7. What are some common signs of a faulty connector? Intermittent connections, flickering lights, or complete system failure.

8. What should I do if I'm unsure about the replacement process? Consult a qualified technician.

In conclusion, understanding how to replace a wire harness connector is a valuable skill for anyone who deals with electrical systems. Whether you’re a DIY enthusiast tackling a home repair or a professional technician troubleshooting complex equipment, mastering this process can save you time, money, and frustration. While the task may seem daunting at first, breaking it down into manageable steps, using the right tools, and following best practices can empower you to tackle this repair with confidence. From restoring a flickering headlight to ensuring the smooth operation of critical equipment, the ability to replace a wire harness connector offers a pathway to a more reliable and functional electrical world.

Adorable kitten gifs a celebration of cuteness

Del rio fire pit gas valve replacement guide

Finding the right doctor understanding karen chang chen md