Decoding the Three Post Solenoid Test

There's a quiet hum, a subtle click, and a mechanism springs to life. This often-unseen action is frequently the work of a solenoid, a crucial electromechanical component found in countless applications, from automobiles to washing machines. Understanding the functionality of these devices, particularly the three-post variety, is essential for troubleshooting and maintenance. This exploration delves into the intricacies of three-post solenoid testing, offering a practical guide to unraveling its mysteries.

Imagine a car door locking smoothly, a washing machine filling with water, or a vending machine dispensing a snack. Behind these actions, a three-post solenoid might be orchestrating the movement. These devices convert electrical energy into mechanical motion, acting as electrically controlled switches or valves. But what happens when this intricate dance falters? How do you pinpoint the source of the problem? This is where the art of three-post solenoid testing comes into play. This article offers a detailed roadmap for diagnosing and resolving solenoid issues.

The journey into the world of solenoid testing begins with understanding its fundamental principles. A three-post solenoid, unlike its two-post counterpart, offers greater control and versatility. The additional post provides an extra layer of switching capability, allowing for more complex operations. This nuanced design, while offering advantages, also introduces unique testing considerations. Grasping the core principles of how these solenoids operate is crucial for effective testing.

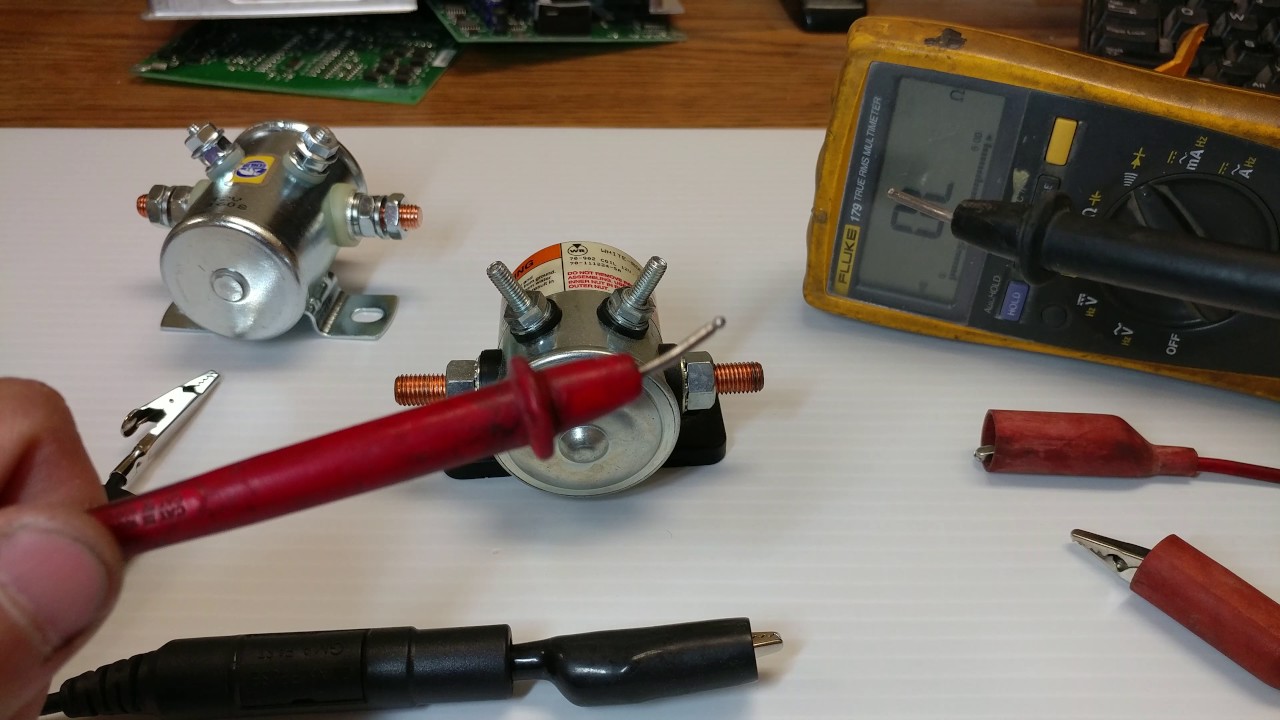

Checking a three-post solenoid involves examining its electrical and mechanical aspects. This might entail using a multimeter to assess continuity and voltage, or physically inspecting the solenoid for signs of damage or wear. A methodical approach is key to accurate diagnosis. This article aims to provide a comprehensive guide to these testing procedures, enabling you to confidently troubleshoot and repair these essential components.

From automotive starters to industrial machinery, three-post solenoids play a vital role in a wide range of applications. Their reliable operation is often critical for the proper functioning of larger systems. Therefore, knowing how to effectively test these solenoids is an invaluable skill for anyone working with electromechanical systems. This article will equip you with the knowledge and practical steps to ensure optimal solenoid performance.

The three-post solenoid’s history is intertwined with the development of electromagnetism and its application in practical devices. Early solenoids paved the way for the more sophisticated three-post design, offering enhanced control and flexibility. The importance of testing these devices stems from their critical role in various systems. A malfunctioning solenoid can disrupt operations, causing anything from a minor inconvenience to a major system failure. Common issues encountered when testing these solenoids include open circuits, shorts, and mechanical sticking.

Testing a three-post solenoid involves verifying its electrical integrity and mechanical functionality. Using a multimeter, you can check for continuity between the posts to ensure the coil is not open. Applying a controlled voltage to the solenoid and observing its mechanical action can reveal whether it's engaging and releasing correctly. A simple example is testing a starter solenoid in a car. Applying power to the appropriate terminals should engage the starter motor. If it doesn't, further testing is needed.

Benefits of testing include preventing costly repairs, ensuring system reliability, and minimizing downtime. For example, testing a washing machine solenoid before it fails completely can save you from a flooded laundry room. Regular testing in industrial settings can prevent production line shutdowns. Proactive testing also ensures the longevity of the solenoid itself, maximizing its lifespan.

A step-by-step guide involves disconnecting the solenoid, visually inspecting it, using a multimeter to test for continuity and voltage, and applying power to check for proper engagement. A checklist can include items like checking for loose connections, ensuring proper voltage supply, and verifying mechanical movement.

Advantages and Disadvantages of Testing a Three Post Solenoid

| Advantages | Disadvantages |

|---|---|

| Prevents costly repairs | Requires some technical knowledge |

| Ensures system reliability | Can be time-consuming in complex systems |

| Minimizes downtime | Requires specialized tools in some cases |

Best practices include using the correct testing equipment, following safety procedures, and documenting test results.

Real-world examples include testing solenoids in automobiles, HVAC systems, and industrial machinery. Challenges might include accessing the solenoid in tight spaces or dealing with complex wiring. Solutions involve using specialized tools and consulting wiring diagrams.

FAQs address common questions about testing procedures, troubleshooting tips, and identifying specific solenoid issues.

Tips and tricks include using jumper wires for testing, checking for corrosion on terminals, and using protective gear when working with electrical components.

In conclusion, mastering the art of three-post solenoid testing empowers you to maintain the smooth operation of countless systems, from everyday appliances to complex industrial machinery. This comprehensive guide, covering everything from basic principles to advanced troubleshooting, provides the knowledge and practical steps necessary for effective solenoid testing. By understanding the nuances of these vital components, you can prevent costly repairs, ensure system reliability, and minimize downtime. Embrace the challenge, explore the intricacies of the three-post solenoid, and unlock the potential for seamless electromechanical performance. This proactive approach not only safeguards your equipment but also cultivates a deeper understanding of the technology that powers our modern world. Don’t hesitate to delve further into the resources available online and refine your testing skills to become a true master of solenoid maintenance.

Unlocking fm24 potential top players to transform your team

Unlocking wordle success mashable style

Locked out reclaim your yahoo mail access