Unlocking Pneumatic Power: Understanding System Diagram Symbols

Imagine a silent, invisible force powering complex machinery, from automated assembly lines to robotic arms. This force is pneumatics, and understanding its language – the pneumatic system diagram symbols – is crucial for anyone working with these powerful systems. These symbols are the building blocks of efficient design, troubleshooting, and maintenance. Without a clear understanding of these visual cues, navigating the intricacies of pneumatic systems can be like trying to read a book in a language you don't know.

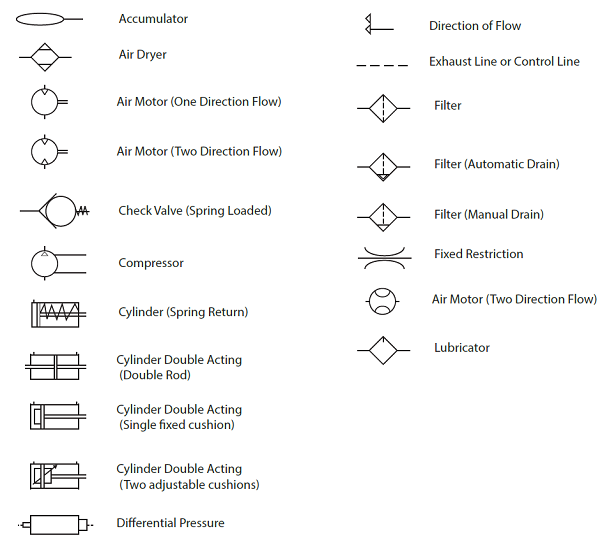

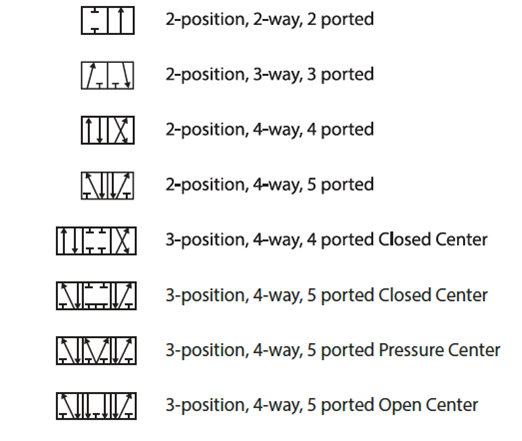

Pneumatic system diagrams provide a visual roadmap of how compressed air powers various components. These diagrams utilize a standardized set of symbols representing different elements like compressors, valves, actuators, and filters. This standardized language allows engineers and technicians worldwide to communicate and collaborate effectively, regardless of their native language. Mastering these symbols opens up a world of understanding about how these systems function and how to optimize their performance.

The history of pneumatic system diagram symbols is intertwined with the development of pneumatics itself. As pneumatic systems became more complex, the need for a standardized visual language became increasingly evident. Early diagrams were often inconsistent and varied between manufacturers, leading to confusion and misinterpretations. The development of international standards, such as ISO 1219-1, brought clarity and consistency to pneumatic circuit diagrams, ensuring that a symbol representing a directional control valve meant the same thing in Germany as it did in Japan.

These symbols are not mere graphic representations; they are essential for effective communication and efficient operation. Imagine trying to troubleshoot a complex pneumatic system without a diagram; it would be like searching for a needle in a haystack. Pneumatic symbols provide a clear and concise overview of the entire system, enabling technicians to quickly identify problems and implement solutions. Furthermore, standardized symbols ensure that everyone involved in the design, installation, and maintenance of the system is on the same page, reducing errors and improving safety.

One of the main challenges related to pneumatic system diagram symbols is ensuring everyone involved understands them correctly. Misinterpreting a symbol can lead to costly errors and safety hazards. Therefore, proper training and education on these symbols are vital. Resources like online tutorials, textbooks, and specialized software can help individuals develop a comprehensive understanding of pneumatic symbology, empowering them to work effectively with these dynamic systems.

A simple example: the symbol for a single-acting cylinder is a rectangle with a single arrow pointing inwards, indicating air flow pushing the piston in one direction. A double-acting cylinder symbol has arrows pointing both inwards and outwards, showing air flow controlling piston movement in both directions.

Three key benefits of using standardized pneumatic symbols are improved communication, enhanced troubleshooting capabilities, and increased safety. Standardized communication facilitates collaboration between engineers and technicians globally. Enhanced troubleshooting is achieved through a clear visual representation of the system. Increased safety is a direct result of clear communication and accurate system understanding, minimizing the risk of misinterpretations that could lead to accidents.

Advantages and Disadvantages of Using Pneumatic System Diagram Symbols

| Advantages | Disadvantages |

|---|---|

| Clear communication and understanding | Requires training and familiarization |

| Efficient troubleshooting | Potential for misinterpretation if not properly understood |

| Enhanced safety | Can be complex for very large systems |

Five best practices for implementing pneumatic symbols include: adhering to international standards (like ISO 1219-1), using clear and concise labeling, maintaining consistency throughout the diagram, using software tools for creating diagrams, and ensuring all team members are properly trained on symbol interpretation.

Five real-world examples where pneumatic system diagrams are essential include: automated assembly lines in manufacturing, robotic systems in various industries, packaging machinery, material handling systems, and braking systems in heavy vehicles.

Five common challenges and solutions related to pneumatic symbols: 1. Lack of training – Solution: implement comprehensive training programs. 2. Inconsistent use of symbols – Solution: enforce adherence to international standards. 3. Complex diagrams for large systems – Solution: utilize software tools for clarity and organization. 4. Difficulty updating paper-based diagrams – Solution: switch to digital diagramming software. 5. Misinterpretation of symbols – Solution: regular review and refresher training.

Frequently Asked Questions:

1. What is the significance of a triangle in a pneumatic diagram? - A triangle typically represents a directional control valve.

2. How is a compressor represented? - Typically by a circle with an intake and discharge line.

3. What does a silencer symbol look like? - Often a rectangle with a series of baffles inside.

4. How is a filter represented? - By a rectangle with a filter element symbol inside.

5. What does a pressure regulator symbol depict? - Usually a device with an adjustable spring and diaphragm.

6. How is an actuator shown? - Often by a cylinder or rotary actuator symbol.

7. What does a flow control valve symbol represent? - A valve with an adjustable restriction.

8. How is a check valve symbolized? - By a symbol that allows flow in one direction only.

Tips and tricks for working with pneumatic system diagrams include using color-coding for different sections, clearly labeling all components, and utilizing software with built-in symbol libraries for creating and editing diagrams.

In conclusion, understanding pneumatic system diagram symbols is paramount for anyone working with pneumatic systems. These symbols are not just abstract shapes; they are the key to unlocking the full potential of pneumatic power. From simplifying complex designs to enabling efficient troubleshooting, these symbols provide a powerful tool for engineers, technicians, and operators. By mastering the language of pneumatics, we can design, operate, and maintain these systems with greater efficiency and safety. Investing in proper training and adhering to best practices ensures clear communication and reduces the risk of errors, ultimately leading to smoother operations and enhanced productivity. Embracing these symbols as an essential part of pneumatic system management empowers us to harness the full potential of this versatile technology.

Unlocking the rav4 primes cargo capacity a deep dive

Unlocking the toyota rav4 price puzzle your guide to smart buying

Ac vacuuming boost your cooling efficiency